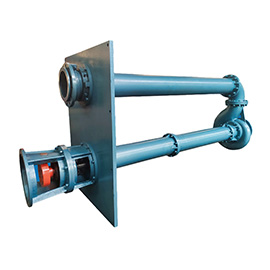

Description

LONGTERM® LYJ Vertical Slurry Pump is a cantilever sump pump,Which work submerged to transport high abrasive and high density slurries with large particles.It doesn’t need any seal water. Ceramics lined, hard metal lined or fully rubber lined fitted.High capacity double suction semi-open impeller design.and suction agitator is also available.

Working Condition:

Capacity: 5.3~600 m³/h

Head: 6-40 m

Speed:730~1480 r/min

Working Temperature:≤105℃

Materials: Ceramics,HT200, QT600, 304, 304L, 316L, 317L, 904L,CD4.

Max Weight Concentration of Allowable Transferred Solid-liquid Mixture: Mortar(Slurry) and Coal Slurry≤45%, Pulp and Dense Medium≤60%

Normal Through Size:56% allowable intermittent through max size.

Design features:

1.Vertical,Submerged,Cantilevered shaft sump slurry pump.

2.Bearing Assembly – The bearings, shaft and housing are generously proportioned to avoid problems associated with the operation of cantilevered shafts in the first critical speed zones.

3.Column Assembly – Completely fabricated from antiwear carbon steel. The LYJ(R) model is rubber covered.

4.Shaft – Different length of the pump drive shaft or suction extension pipe could be selected

5.Casing – LYJ(R) has a simple bolt-on attachment to the base of the column.

6.Impeller – Double suction semi-open impeller design, Wear resistant alloys, polyurethane and moulded elastomer impellers are interchangeable.

7.Upper Strainer – Drop-in metal mesh; snap-on elastomer or polyurethane for LYJ and LYJ(R) pumps. Strainers fit in column openings.

8.Lower Strainer – Bolted metal or polyurethane for LYJ pumps; moulded snap-on elastomer for LYJ(R) pumps.

9.Discharge Pipe – Metal for LYJ pumps; Rubber covered for LYJ(R) pumps. All wetted metal parts are completely rust protected

10..Agitator option keeps solids in suspension,Alternatively, a mechanical agitator is fitted to an extended shaft protruding from the impeller eye.

11.Don’t need any seal and seal water.

LONGTERM® LYJ Vertical Slurry Pump is widely apply to mines, metallurgy, power, coal, chemical engineering, building materials and flue gas desulphurization peripheral system etc., and are used for delivering slurry with abrasive particles or corrosive slurry.